Präzision als Berufung – Erhöhung der Prozesssicherheit in der Spritzgussindustrie mittels Metallseparatoren

Präzision als Berufung – Erhöhung der Prozesssicherheit in der Spritzgussindustrie mittels Metallseparatoren

Präzision ist ein Schlüsselkriterium für die profitable Herstellung von hochleistungsfähigen Kunststoffteilen. Bei der Sola Messwerkzeuge AG helfen leistungsfähige Metallseparatoren zuverlässig Einflüsse auf die Produkt- und Prozessqualität zu vermeiden.

Vom Dachboden zum Industriebetrieb

Die Geschichte von Sola beginnt mit Herrn Ing. Guido Scheyer und seinen Kollegen Sottopietra und Latzel, aus deren Nachnamen sich der Firmenname zusammensetzt. Im Dachgeschoss eines Wohnhauses werden die ersten Wasserwagen gefertigt. In der Gründungszeit ist noch Holz das Material der Wahl, wie auch in vielen anderen Bereichen. Bereits 1957 wurde jedoch zur Verbesserung der Messgenauigkeit Aluminium als Ausgangsprodukt verwendet. Ab 1958 steigt man auch in die Kunststofffertigung ein. Zunächst mit einer mechanischen Spritzgussmaschine, die noch heute im Eingangsbereich der Fertigungshalle des Sola Kunststoffwerks zu besichtigen ist. 1969 startet die Produktion im neuen Werk am heutigen Hauptsitz in Götzis, Österreich. Hier beginnt auch für Sola die Ära der Acrylglas-Libelle, deren Verschluss mittels Ultraschall patentiert wurde.

Die Produktpalette wurde in den folgenden Jahren um viele Präzisionswerkzeuge wie Rollbandmaße, Meterstäbe oder auch Lasermessgeräte erweitert. Dementsprechend stieg auch der Umfang der Kunststoffproduktion. Ergänzt wurde dieser steigende Eigenbedarf durch einen hohen Anteil an Fremdfertigung, beispielsweise hochwertige Beschläge für Gartenmöbel. Hierzu wurde die Fertigung 2003 in ein eigenes Gebäude ausgelagert, dem heutigen Werk 3. Insgesamt 45 Spritzgussmaschinen von 50 bis 300 Tonnen Schließkraft verarbeiten hier jährlich über 2.500 Tonnen Kunststoffe. „Steigende Produktionszahlen und der Wille zur Optimierung haben uns die letzten Jahre konstant auf Trab gehalten. Die Verminderung von Ausschuss und hohe Standzeiten verbessern sowohl die Wirtschaftlichkeit als auch die Nachhaltigkeit unserer Produkte“, so Guido Timmermans, Bereichsleiter Kunststofffertigung. Damit beschreitet Sola weiter den vor vielen Jahren mit der ersten hölzernen Wasserwaage eingeschlagenen Weg, mit kompromissloser Präzision und Zuverlässigkeit langfristigen Erfolg zu schaffen.

Einflüsse von Innen und Außen

Die Herstellung von Kunststoffteilen im Spritzgussverfahren ist verschiedenen Einflüssen ausgesetzt. Diese haben, abhängig von der Art des herzustellenden Teils, stärkere oder schwächere Auswirkungen auf die Qualität und die Wirtschaftlichkeit. Fremdkörpereintrag stellt hier sowohl unter Umständen für den Spritzgussprozess wie auch unter Umständen für das fertige Teil, ein großes Problem dar. Gerade metallische Fremdkörper stellen hier einen relevanten Anteil an möglichen Verunreinigungen dar.

Von außen werden Metallverunreinigungen über die Rohstoffe eingetragen. Dies kann über Recyclate, aber auch über Neuware oder Masterbatch erfolgen. Metalle kommen hier als Einschlüsse, oder auch als lose Teile in Verpackungseinheit oder Tanklaster vor. Auch die eigene Produktions-umgebung kann durch Montage- und Wartungsarbeiten, hauseigene Zerkleinerungsanlagen oder schlichte Unaufmerksamkeiten für das Einbringen von Metallteilen sorgen. Späne, Kabeladern oder Beilagscheiben sind typische Beispiele solcher Fremdkörper. Gelangen diese Teile in die Plastifizierungseinheit, können sie diverse Probleme verursachen. Das offensichtlichste ist eine Verstopfung der Verschlussdüse oder bei größeren Teilen sogar eine Beschädigung der Schnecke. Dies verursacht in der Folge meist längere Wartungsarbeiten und Maschinenstops, bei Sola je nach verarbeitetem Material mehrmals pro Woche und Anlage.

Weniger beachtet, aber dennoch problematisch ist der Einfluss von Metallen im Schmelzverfahren. Fremdstoffe beeinflussen den Ablauf der Plastifizierung und können so speziell bei sensiblen Formteilen Qualitätsprobleme auslösen. Zuletzt sind natürlich unsichtbar eingeschlossene Metallpartikel eine Gefahr für die strukturelle Integrität der fertigen Teile.

Risiken reduzieren

Bei der Entwicklung ihrer Strategie zur Risikominimierung sollten für Sola Einträge von außen auf ein Minimum beschränkt werden. Dies wurde im Zuge der Auswahl qualitativ hochwertiger Zulieferer mit entsprechenden Kapazitäten in der Metallerkennung erledigt. Regelmäßige Schulungen für das Personal an den Spritzgussmaschinen, der Werkstechnik, sowie für Fremdfirmen sind ein weiterer Baustein, um das Aufkommen von Fremdkörpern zu verringern. Trotz dieser Maßnahmen war jedoch immer noch nicht die Prozessqualität erreicht, die ein Hersteller hochpräziser Messtechnik anstrebt. Eine finale Sicherungsmaßnahme am Maschineneinlauf musste gefunden werden. An dieser Einbauposition gibt es zwei weitverbreitete Möglichkeiten zur Materialkontrolle. Zum einen sind dies Magnete in verschiedenen Ausführungen. Diese haben jedoch den Nachteil, nur magnetische Metalle von der Anlage abzuhalten. Im Schwerpunkt bedeutet dies Eisen, sowie manche Arten von verformten Edelstählen. Um jedoch sicher alle Metallarten automatisch aus dem Materialstrom auszutragen, bietet sich als Lösung der elektronische Metallseparator an.

Nur eine Option für Metallfreiheit

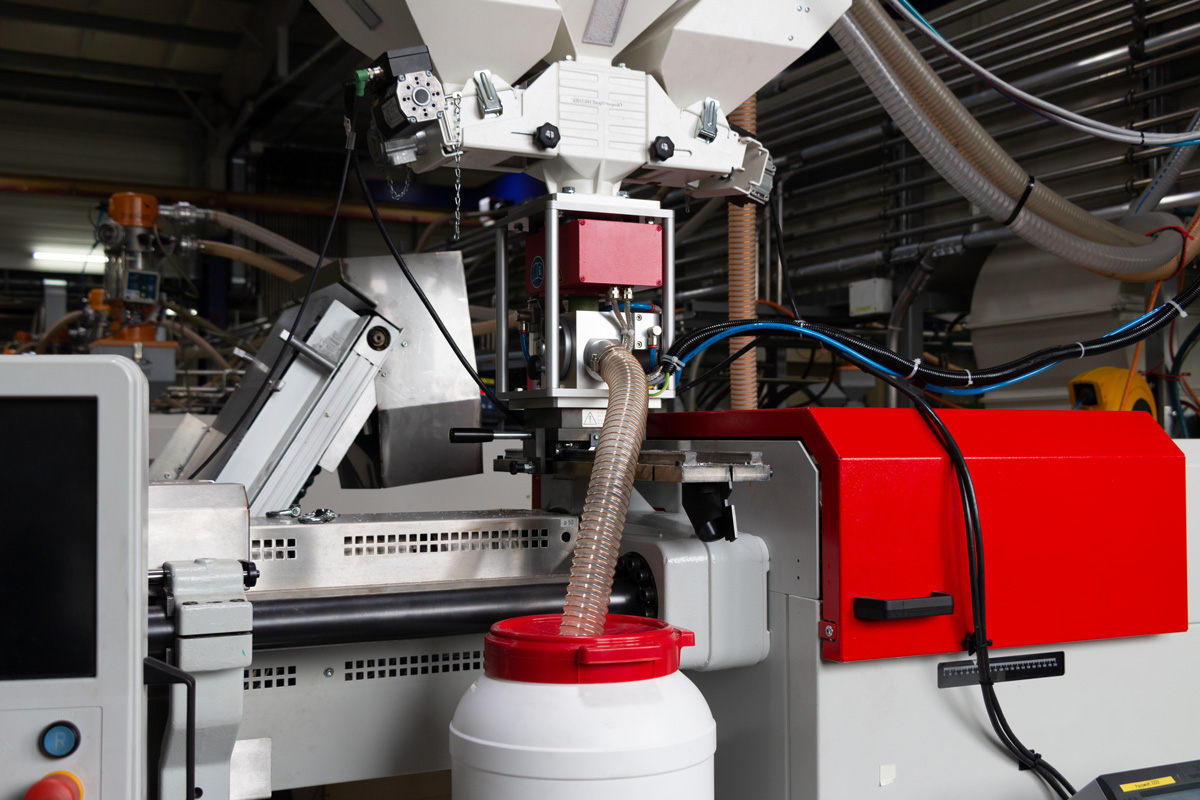

Allmetallabscheider für den Maschineneinzug sind von verschiedenen Herstellern verfügbar. Sie funktionieren nach dem sogenannten „balanced-coil“ Prinzip. Nach Testinstallationen viel die Entscheidung auf den Plastron 05 K. Das Gerät wurde produziert von der Mesutronic GmbH aus Kirchberg im Wald. Der kompakte Metallseparator konnte speziell in den Bereichen Erkennungsgenauigkeit und Zuverlässigkeit überzeugen. Außerdem lieferten die Mitarbeiter der Mesutronic die beste Leistung bei der Servicequalität in den Phasen Projektierung, Installation und Inbetriebnahme.

„Nach dem Einbau des Testgeräts von Mesutronic konnten wir unsere Maschinenstillstände nochmals deutlich senken. Damit war die finale Entscheidung, die relevantesten Anlagen mit Metallseparatoren auszustatten, gefallen.“ so Michel Gorga von der Werkstechnik bei Sola.

Aktuell schützen dreizehn Metallseparatoren die vulnerabelsten Spritzgussmaschinen. Neben der werkzeuglosen Zerlegbarkeit der Ausscheideeinheit bei Material- oder Farbwechsel bieten die Geräte eine sehr hohe Erkennungsgenauigkeit. Selbst feine Späne oder Drahtstücke aus Edelstahl, Kupfer oder Aluminium werden sicher erkannt und mit minimalem Materialverlust ausgetragen. So haben die beiden Spezialisten für Messtechnik nicht nur über die nahezu identische Firmenfarbe zusammengefunden, sondern auch durch den gemeinsamen Anspruch auf Präzision und Zuverlässigkeit ohne Kompromisse.