Kirchberg im Wald. The K trade fair opens its gates once again in Düsseldorf on Wednesday, 19 October 2016. The trade fair is the absolute highlight in the industry and the starting point for trendsetting decisions for process, product and problem solutions in plastics processing.

We interviewed our product manager Jörg Pattberg about this industry highlight:

Mr Pattberg, how important is the plastics market to Mesutronic GmbH?

JP: The plastics industry is one of our most important business segments. The roots of Mesutronic, which was founded nearly 25 years ago, lie here. Over the years both our portfolio and our network of technicians and sales specialists has grown continuously. Our high presence at the most renowned plant manufacturers and end customers in this sector proves it. And we will, of course, continue to focus on this market in future.

For product manager Jörg Pattberg is the plastics industry one of the main business segments of the Mesutronic GmbH.

How important is the K trade fair to Mesutronic?

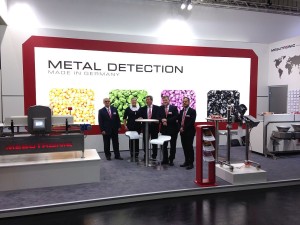

JP: To be internationally successful in the plastics industry we have to be present for our customers. Direct contact is very important to us. The K trade fair is a good place, not only to meet our customers en masse, but also to generate new contacts and to show them our proven metal detection technology. Our presence began here in the founding years and we will continue in future to be present for our customers and joint exhibitors within the framework of the trade fair.

What are you expecting from the K trade fair?

JP: Business transactions at trade fairs have receded more and more into the background in recent years, so we are focusing on communication and customer ties. That is also reflected by our new booth concept, which backs off a little from pure presentation. We see ourselves as partners and want to convey inclusion and enjoyment in contact at every level.

Mesutronic stands for innovative devices; what are Mesutronic’s plans with regard to the plastics industry? How do you stand with regard to Industry 4.0?

JP: A very interesting development project for the plastics sector is currently in progress in the company. No further details will be available until the end of next year, however. Industry 4.0 is not a new topic for us. We made provision more than 10 years ago for the simple linking of our machines to higher-level systems, both for data acquisition and for external control options. The most diverse communication methods are available to the customer today. That’s why we see many opportunities here and consider ourselves to be ideally prepared.

Our exhibition team is looking forward to present reliable metal surch technology on the new Booth.