Blog

Gentle ejection for sensitive products: A special system for vegan pudding

At Mesutronic, we continuously develop customized solutions tailored to our customers’ specific requirements. One of our latest innovations is a specially designed inspection and rejection system for a leading dairy product manufacturer who is tackling the challenge of product safety for delicate foods.

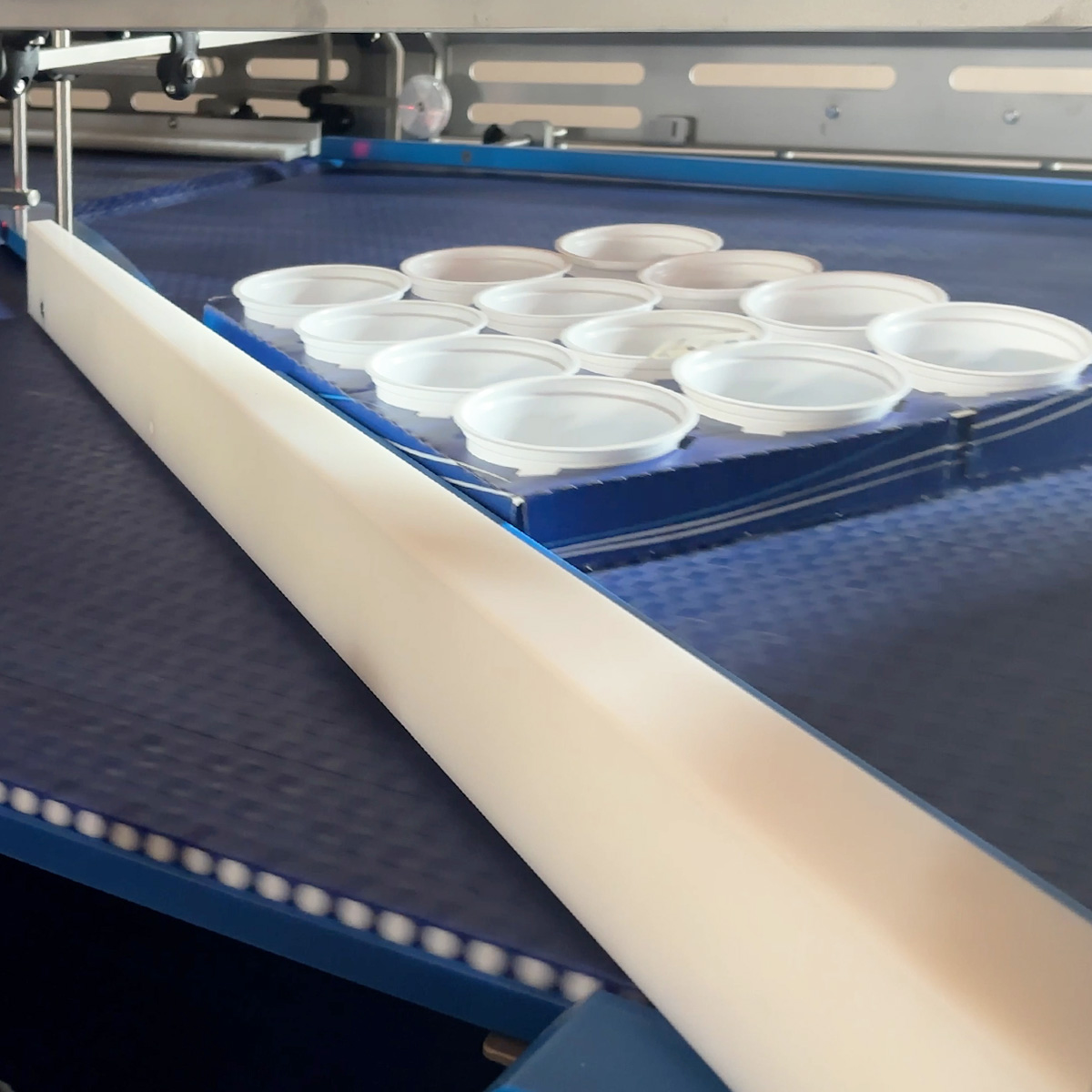

The challenge: Hot, vegan pudding in trays

The customer produces vegan pudding, which is transported in full trays directly after filling – while still hot. If foreign objects or quality defects are detected, the entire tray is ejected, even though typically only one pudding cup is affected. Potential contaminants include shards of glass, metal wires, or dense plastic pieces. The problem: The thin pudding in neighboring cups can be negatively affected by sudden ejection. This leads to unnecessary food waste, as the remaining products can no longer be sold.

The Mesutronic solution: Gentle deflection and timed discharge

To address this challenge, Mesutronic developed an especially gentle and precise ejection mechanism:

- Swivel arm deflection: Affected trays are gently deflected from the main conveyor line using a specially designed swivel arm. This method minimizes vibrations and preserves the integrity of the remaining pudding cups in the tray.

- Timed discharge conveyor: After deflection, trays are transferred to a timed discharge conveyor. This conveyor is designed to move trays individually and in a controlled manner, effectively preventing collisions and backups at the end of the line.

Benefits of the new system:

- Minimized food waste: Only the actually affected products are sorted out thanks to precise and gentle individual ejection.

- Preservation of product quality: The gentle handling prevents negative effects on the consistency and quality of the unaffected pudding cups.

- Seamless integration: Mesutronic also supplied the conveyor for the good products, ensuring smooth integration of the complete line into the customer’s existing production environment.

This special system is an excellent example of how Mesutronic delivers customized solutions through innovative engineering and a deep understanding of production processes – solutions that not only boost efficiency but also promote sustainability in food production.