Blog

With the Greatest Care: How Frozen Vegetables Safely Make Their Way into Baby Food

When it comes to producing baby food, there is no room for compromise on safety and quality.

One of the greatest challenges lies in processing frozen bulk goods such as broccoli and peas. The varying product sizes and strict hygiene requirements call for a customized solution that ensures maximum precision.

The Challenge: Frozen Bulk Goods with High Demands

Processing frozen vegetables for baby food presents a unique set of challenges:

- Product variety and size: From small peas (5–10 mm) to larger broccoli pieces (up to 50 mm), the systems must be capable of handling a wide range of product sizes.

- Temperature and moisture: With product temperatures ranging from -15 to +5 °C and residual moisture of 70–90%, the goods are extremely sensitive. At the same time, the system must operate reliably in an environment with ambient temperatures between 15 and 30 °C.

- Maximum hygiene: Perhaps the most important aspect is meeting the highest hygienic standards. Every step must be designed to prevent contamination.

A decisive factor in this process is the metal detector. The system uses the METRON 07 CI – a high-end tunnel detector with integrated electronics that reliably detects even the smallest metal particles. It represents the premium choice for pure metal detection and is indispensable in ensuring that the strict safety standards for baby food are met during final inspection with minimal product rejection. To achieve this, potential metal contamination must already be reduced to an absolute minimum at the very beginning of the production process.

The Solution: A Customized Design for the Highest Hygiene Standards

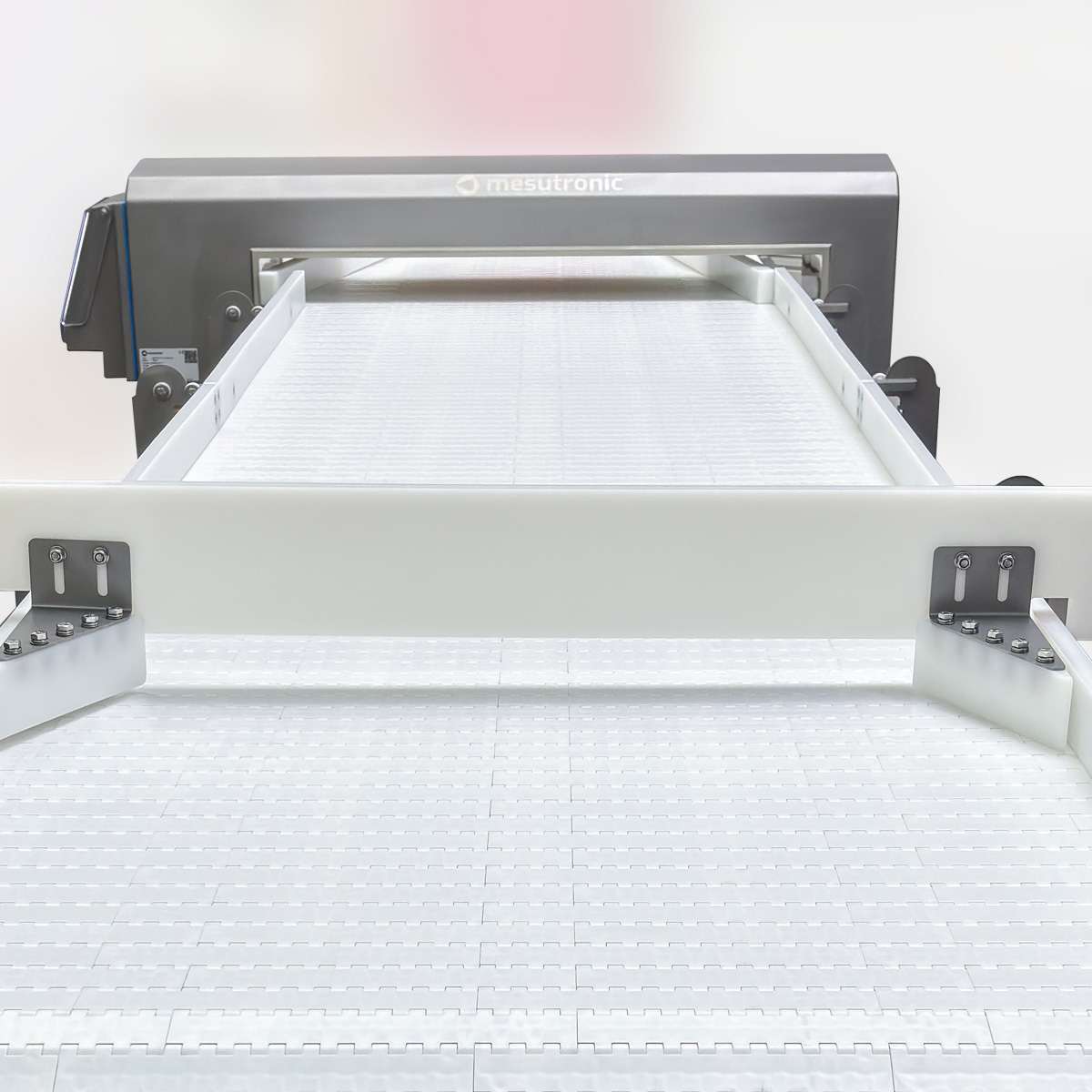

The greatest challenge is combining these processes with the strictest hygiene requirements. For this purpose, Mesutronic developed a customer-specific special version based on the TRANSTRON C conveyor system, ensuring hygienically flawless processing.

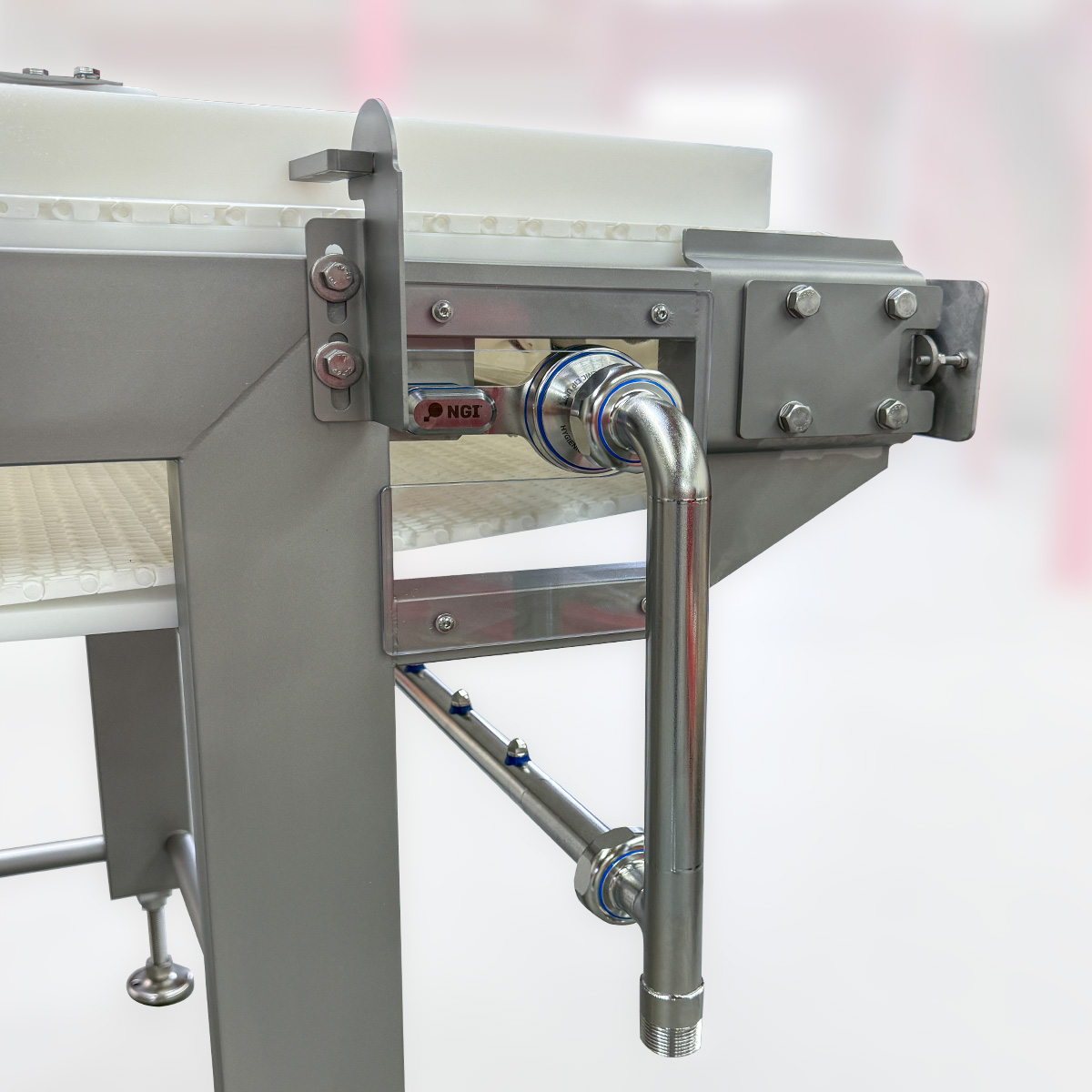

- Special design for maximum hygiene: The customized TRANSTRON C conveyor belt features foldable guide rails, height limiters at the product feed, and a hygienic CIP unit (Cleaning in Place) for automatic cleaning of the chain-link belt. This allows for effective removal of residues and prevents cross-contamination. All other sensitive components were implemented in hygienic or wash-down versions.

- Efficient belt discharge: At the end of the conveyor, individually adjustable guide rails and a spring-loaded scraper ensure smooth product transfer without residue sticking to the belt. This minimizes contamination risks.

- Highest detection accuracy: Thanks to the METRON 07 CI and its advanced technology, foreign objects are reliably detected, ensuring safe further processing of the product.

Height limiter at the product feed

Foldable guide rails

CIP unit

Conclusion

Processing frozen vegetables for baby food is a showcase example of how Mesutronic, through innovative engineering and profound process expertise, delivers tailored solutions that not only increase efficiency but, above all, guarantee the safety of the smallest consumers. Systems such as the TRANSTRON C conveyor in combination with the METRON 07 CI metal detector form part of a comprehensive chain of traceability and foreign object management, enabling parents to offer their children a product with complete peace of mind.